A preflight editor is important for prepress automation

The earlier, the better

Automated processes can be used to optimize company workflows as early as the prepress stage.

In printing, it’s a bit like in soccer: at the end, the goal scorer is celebrated by his fans, but without good prepress work by his teammates, he would hardly have scored – and prepress in digital printing is just as important for subsequent printing: “Many prepress processes can be standardized and thus simplified, which in turn influences the downstream processes in digital printing and digital cutting. This helps to save time, eliminate any sources of errors, and simplify staff training,” explains Lars Bendixen, Segment Manager Graphics at Zünd Systemtechnik. Saving as little as five to ten minutes of time on each job has a big impact over the course of a year, adds Tom Elton, Product Manager CLOUDFLOW at HYBRID Software, on the positive effects of investing in automation tools.

In the right places

The first step in automating a prepress operation is to standardize processes such as file delivery. Only then should a company look at how automating certain prepress processes can improve internal workflows. According to Tom Elton, this includes repeatable administrative tasks such as adding info panels to each job, manual imposition when all job details are available, and file submission to a customer when their contact details and file submission platform are available; this can prevent “wasting” skilled prepress staff. “Finding the right digital files in emails or correct trapping specifications in a job bag takes time and talent,” explains Tom Elton.

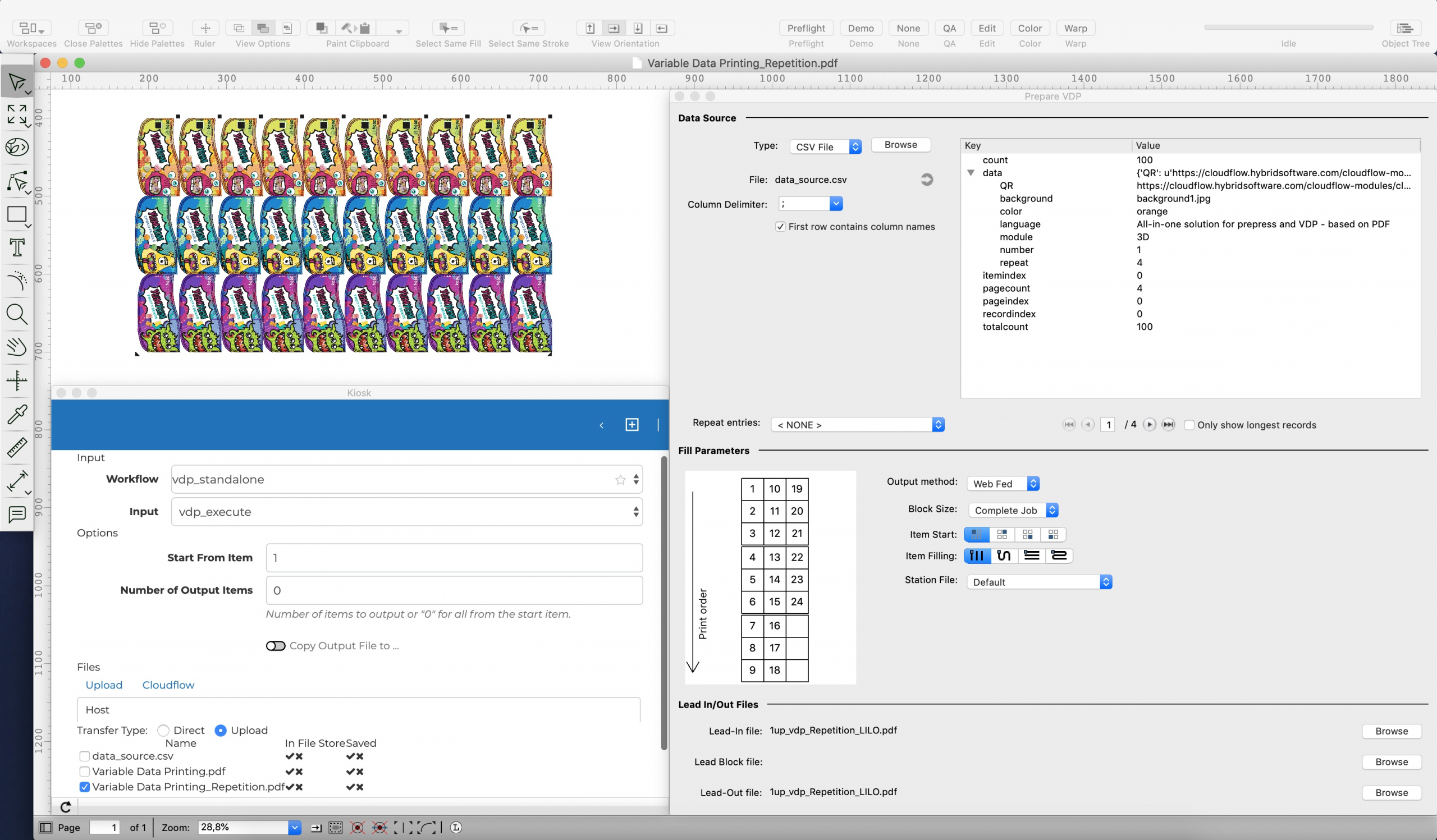

Other areas of prepress that can be standardized or subsequently automated include preflight or prepress activities. The latter includes barcode generation, color conversion, text changes, step-and-repeat, and die export.

Prepress

Prepress software is used to implement the automation options just mentioned. According to Tom Elton, most software tools today allow for easy communication between prepress and downstream printing processes, ensuring that information is passed on. For larger operations with high volumes of print jobs, the HYBRID Software employee recommends standardizing the way operations receive files with standardized or custom upload portals.

An indispensable automation tool for prepress, he says, is first an editor that can seamlessly preflight incoming files. This should have the necessary tools to prepare files for printing, impose and manage inks. In the best case, the end result is a file that is readable by all digital presses. In addition, he says, it helps if the editor generates accounting reports. Despite the many options for automating print preparation, according to Lars Bendixen, a good software tool is also characterized by the ability to make individual configurations. This means that users can decide for themselves which processes should be automated and also intervene in those manually.

Small mistakes, big effect

The aim of prepress automation using software is, on the one hand, to simplify processes and, on the other, to avoid recurring errors that could potentially affect the entire printing process. According to Tom Elton, it’s often small things that add up in the end and cost print providers dearly; examples include uploading the wrong files to a digital job bag or adding the wrong content to the wrong file. Color conversion with the wrong press profile or printing an old version of a file are also mistakes that can happen due to inattention or multitasking. The result is wasted time, materials as well as money; in the worst case, the relationship with the customer suffers. “Errors in prepress are often only detected during cutting: ‘How and where do you position registration marks correctly on the print image, for example?’ ‘How many registration marks are necessary for which type of job?’ or ‘How do different jobs belong correctly arranged on the material, considering the respective finishing – milling, cutting, creasing, etcetera?” are questions that need to be examined in prepress, according to Lars Bendixen, as different materials bring different requirements. Software for automated data preparation can also be helpful here.

Before the final digital output goes to print, it still needs to be checked by a human eye in the last step – in case any errors have crept in during prepress. After all, a highly automated prepress process is of no use to any company if faulty files end up in the further printing process, the result is unusable, and thus more costs and more time are incurred despite automation.

The Future of Prepress

SIP: Do you see any need for improvement in automation software in prepress in the future?

Lars Bendixen (Zünd Systemtechnik): There is room for improvement, for example, in logistics support, with consistent tracking and tracing of jobs based on assigned metadata.

Tom Elton (HYBRID Software): Today, many tools are “open” but still work with outdated technologies. As more and more technology moves to the cloud, it’s important to leverage it and ensure communication between all relevant systems within the enterprise to enable smarter and tighter integration.

SIP: What innovations regarding prepress software can be expected in the near future?

Lars Bendixen: Innovations are planned for Zünd in the area of robotics and for the ZCC Visualizer cutting software.

Tom Elton: Due to more intelligent software and hardware, more detailed data acquisition and more accurate evaluation is possible. I therefore foresee a tighter coupling of more equipment with live feedback and automatic adjustments spanning across the entire enterprise, not only the department.