Intelligent Flexo – The Reliable and Automated Solution for Flexographic Printing from HYBRID Software

Room for Improvement in Flexo printing

HYBRID Software understands that flexo packaging printers’ needs include innovative software so that they are able to print at the best possible quality — efficiently and quickly tackling increasing orders.

To overcome issues faced in recent years, a popular solution in the market has been to print at 4000 dpi combined with a high definition modulated screening algorithm. While this has solved many problems for flexographic printers, it remains a one-dimensional method and introduces press instability as well as slower platemaking imaging speeds – both of which do not bring the printers further to their goal.

HXM Screening Solution in collaboration with Global Graphics

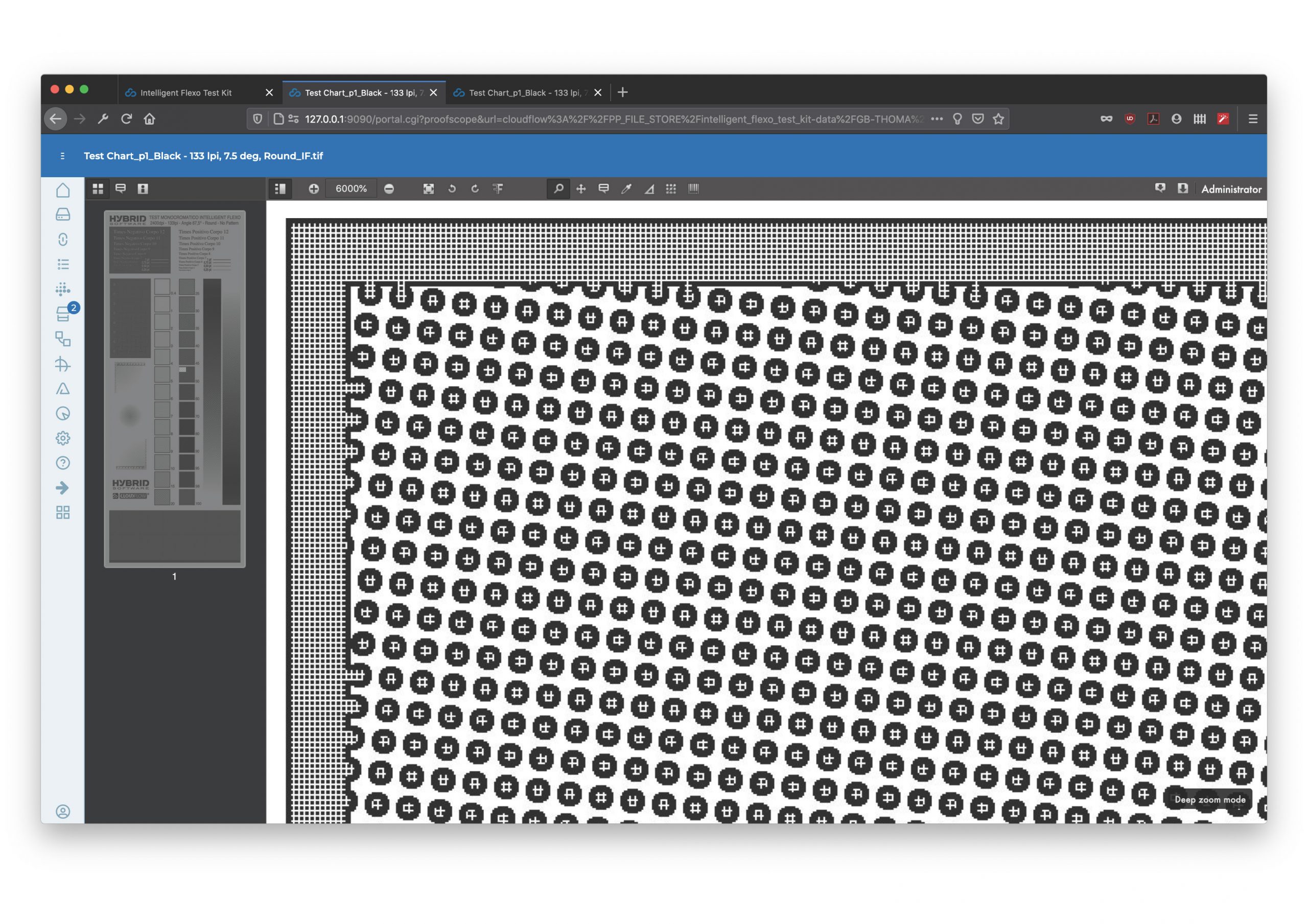

Unlike other systems, we have designed HXM to work with any output device and flexo plate printer. HXM screening combines the advantages of both AM and FM screening and is therefore able to limit the loss of small, printed structures and detail at high line screen rulings by controlling the dot size in the highlight and shadow.

Harlequin Cross Modulated Screening limits the smallest structure produced to be reliably printed on the target system. Once this point is reached within a given HXM screen, structures are removed completely rather than continuing to be reduced in size to create the required tonal range. Therefore, it does not disappear in the light areas or merge in the dark areas, which improves the print quality with smoother tones, flat tints, and gradient transitions.

Intelligent Screening in HYBRID Software’s CLOUDFLOW

With Intelligent Flexo, the market receives finally the solution they have been needing to complete their orders with less errors and at high-speed. Available in HYBRID’s CLOUDFLOW software, the new functionality intelligently applies screening modifications to post-ripped files. As working in post-RIP data allows for more control, CLOUDFLOW users will now be able to identify problem areas in the images which require intervention, before printing on the press, to save time and valuable resources.

Discover more about CLOUDFLOW at here.